The Hall BioProcess™ system provides a sustainable and cost-effective water treatment technology that reactivates contaminated water sources through advanced biological remediation

The Hall BioProcess™ system removes nitrates, perchlorate, selenium, and hexavalent chromium from impacted water by bacteriological

de-nitrification. The patented technology used by the Hall BioProcess™ system has a unique biological treatment that incorporates four main components in the treatment process, achieving the highest post-treatment water quality currently available.

Hall BioProcess™ System Components

Naturally

occurring

bacteria

Suspended Sponge Carriers

The Patented

Hall BioReactor™

Computerized

monitoring system

Hall BioProcess™

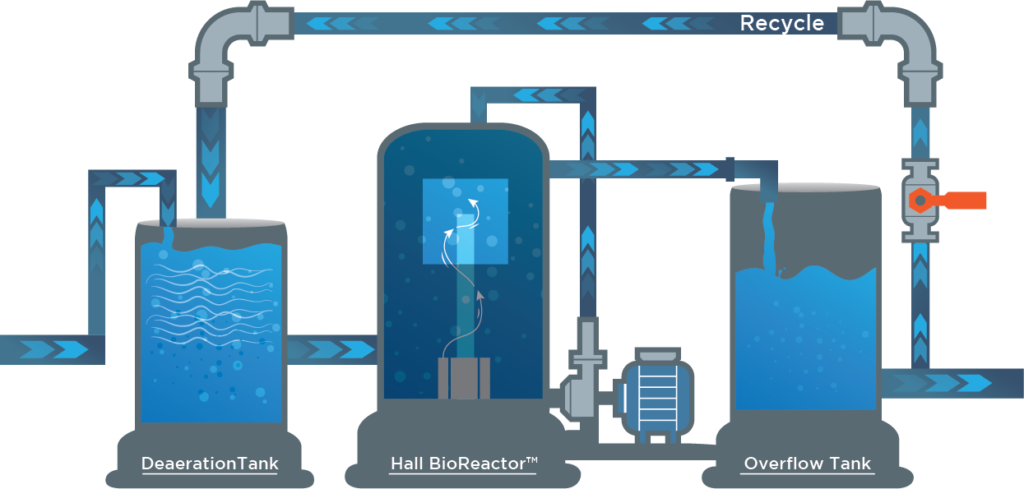

MIH Water’s Hall BioProcess™ systemhas a unique biological treatment process that begins when contaminated water is pumped into the deaeration tank.

Inside this first tank, oxygen is removed from the contaminated water. This removal forces the naturally occurring bacteria to rely on the

nitrates in the contaminated water for oxygen. This nitrate-rich water and oxygen-starved bacteria then flows into the Hall BioReactor™

vessel, which is filled with sponge-like carriers.

These sponge-like carriers have a high surface area, carrying more of the naturally occurring bacteria per particle than any other biological treatment available. These carriers, rich with bacteria, are circulated through the vessel in a continuously stirred environment.

Continuous stirring creates an exceptional environment for the bacteria to “consume” the nitrates from the contaminated water, in search of

oxygen. Once the bacteria have completed their job, the nitrate-free water exits the top of the reactor vessel, and the inert nitrate gas is

expelled into the atmosphere, where it naturally exists. This is the simple, eco-friendly treatment process of the Hall BioProcess™ systems.