Hall BioProcess™ System Difference

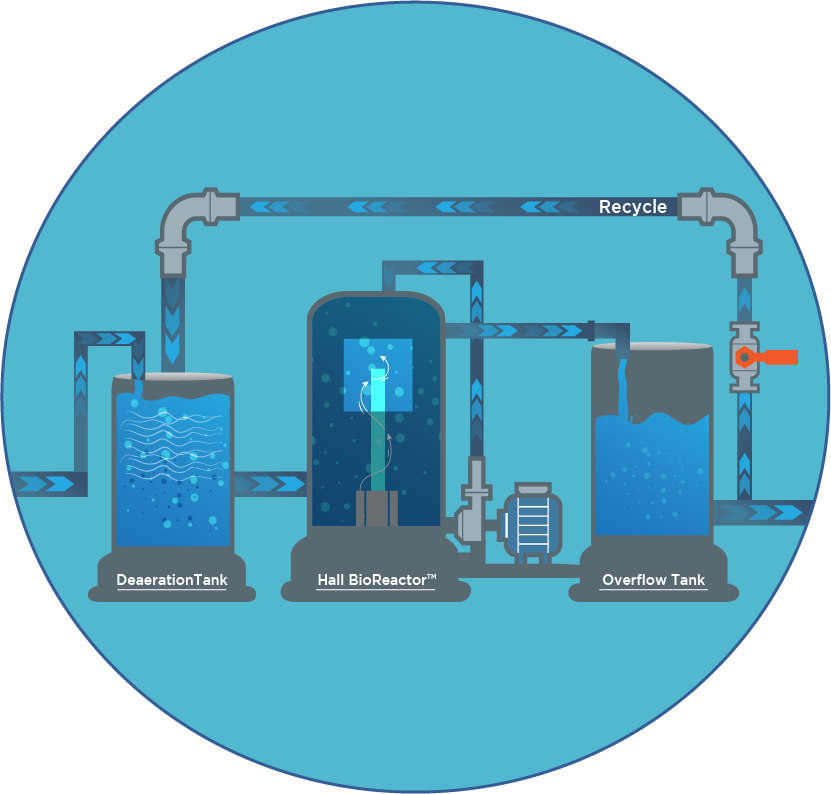

The Hall Process™ system’s treatment differentiation lies in the suspended carrier particles, which have an exceptionally larger surface area than that of the competing biological treatment technologies. Because of this, a higher concentration of bacteria exist in our treatment process, yielding a much higher supply of clean water per treatment cycle.

Additionally, the Hall BioReactor™ vessel’s continuous circulation results in faster remediation by forcing more water, more quickly through the bacteria-dense suspended particles inside the vessel, resulting in an increased amount of treated water, in a shorter amount of time.

Further, because the main process of the system utilizes naturally occurring bacteria, no sludgy waste or excess materials are produced during treatment. The Hall BioProcess™ system’s treatment process yields minimal waste side-stream, results in no contaminated biological materials, and is an entirely sustainable treatment process.

The Hall BioProcess™ system has a unique biological treatment technology that offers many benefits over

current treatment technologies:

Lower Operating Cost

30- 45% lower than the OPEX of competing technologies

Smaller in Size

The system is scalable

Greater Efficiency

Reduces contamination concentrations to nearly 0 ppm

Faster Remediation

Removes contaminates at a faster rate than competitors

No contaminated waste

Produces no side-stream of contaminated materials

Biotechnology Advantages

Uses robust bacterial technology, rather than complex and more expensive chemicals